PLC System Design & Programming

Transforming Industrial Operations Through Advanced Control Systems

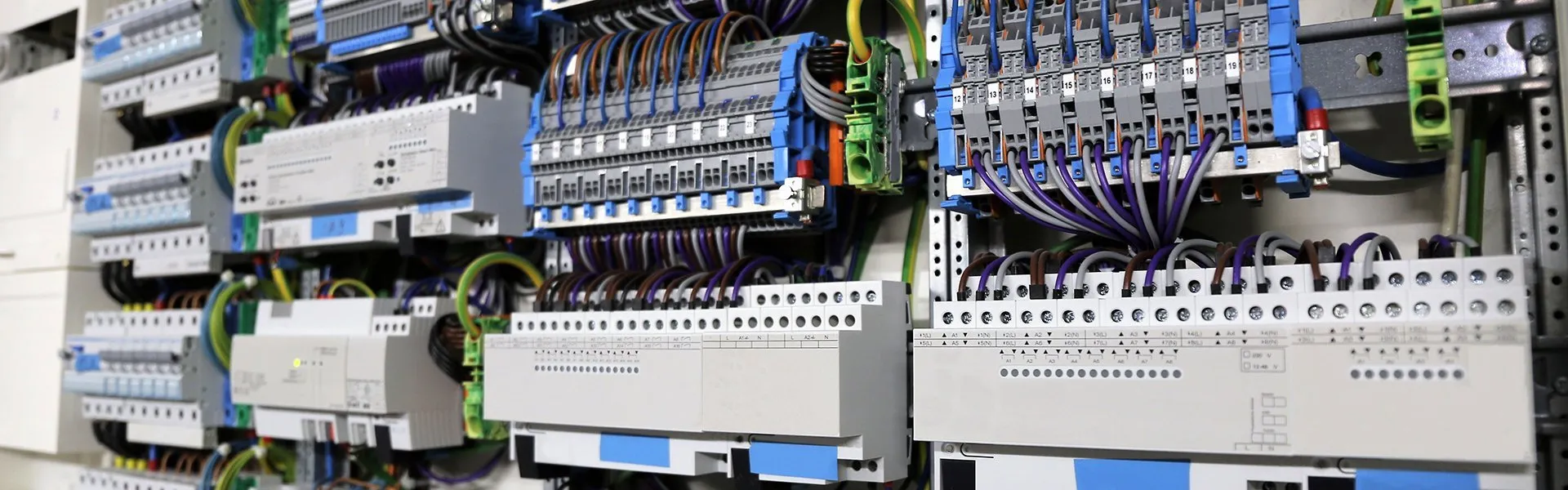

South Coast Automation & Electrical delivers sophisticated PLC solutions that form the backbone of efficient industrial operations across Adelaide's food, beverage and waste processing sectors. Our experienced team designs and implements control systems that enhance production efficiency, improve product consistency and provide detailed operational insights that drive continuous improvement.

With 15 years of industrial automation experience and more than 250 successful implementations, we understand the critical nature of PLC systems within modern manufacturing environments. Our solutions balance technological innovation with practical reliability, ensuring your facility benefits from advanced control capabilities without compromising operational stability.

Comprehensive PLC System Solutions

Our team provides end-to-end PLC system design and implementation services, from initial concept development through to commissioning and ongoing support. We work closely with your operational and maintenance teams to ensure solutions align with your specific production requirements and facility standards.

South Coast Automation & Electrical develops control systems that address immediate operational needs while establishing foundations for future expansion and technological advancement. This forward-thinking approach protects your investment and positions your facility for ongoing efficiency improvements.

PLC Design Capabilities

- Detailed assessment of operational requirements and control objectives

- Development of system architecture and network topology

- I/O listing and component specification

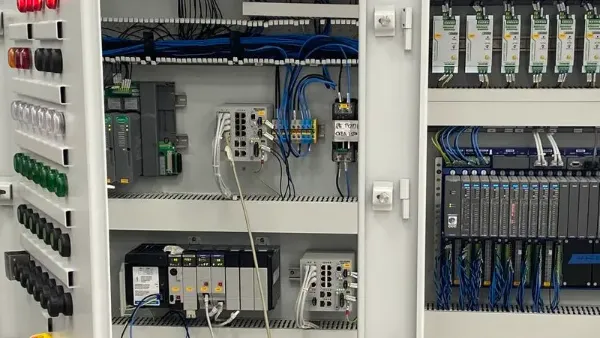

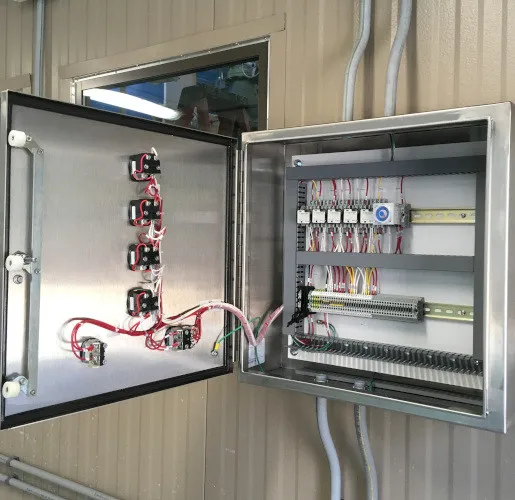

- Electrical design for control cabinets and field devices

- Safety system integration and compliance verification

- User interface design for intuitive operation

- Database structure and recipe management systems

- Remote access provision for monitoring and support

Implementation Expertise

- Professional installation adhering to Australian standards

- Comprehensive control panel assembly and testing

- Structured commissioning processes with minimal disruption

- Detailed system documentation for maintenance reference

- Operator training on system functionality and troubleshooting

- Post-implementation optimization and performance tuning

- Ongoing technical support and system maintenance

- Version control and program backup services

Platform Expertise

We support a wide range of industrial control platforms, ensuring seamless integration with your existing systems or new implementations tailored to your requirements.

- Allen Bradley ControlLogix and CompactLogix

- Siemens S7-300/400 and S7-1200/1500

- Omron CJ and NX series controllers

- Schneider Electric M340 and M580

- Mitsubishi Q series and iQ-R

- B&R X20 system

- GE Fanuc PACSystems

- ABB AC500 series

Programming Languages

Our expertise spans multiple programming environments, allowing us to develop optimized control strategies for any application.

- Ladder Logic (LAD) for intuitive troubleshooting

- Function Block Diagram (FBD) for process control

- Structured Text (ST) for complex algorithms

- Sequential Function Charts (SFC) for step sequencing

- Instruction List (IL) for optimized execution

- Continuous Function Chart (CFC) for custom logic

- High-level language integration with C and C++

- Custom function development for specialized applications

Food Processing Applications

Our control systems ensure product consistency, compliance, and efficiency in food production.

- Recipe management systems with secure access control

- Batching and mixing control with precision weighing

- Temperature and cooking process monitoring

- CIP (Clean-in-Place) automation and verification

- Packaging line control and synchronization

- Product tracking and traceability solutions

- Energy monitoring and optimization controls

- Integration with quality control systems

Beverage Production Applications

We implement automation solutions to optimize formulation, processing, and packaging.

- Blending and mixing control for consistent formulation

- Flow metering and ratio control for beverage products

- Pasteurization and sterilization process control

- Carbonation and pressure monitoring systems

- Bottle filling and packaging line coordination

- Line changeover automation for different products

- CIP sequence control with validation

- Utility management for efficient operation

Start Your PLC System Project

Comprehensive PLC Solutions for Industrial Efficiency and Growth

At South Coast Automation & Electrical, we deliver more than just technology – we provide tailored solutions that address your specific operational challenges while planning for future growth and adaptation.

Contact South Coast Automation & Electrical today to discuss your industrial control system requirements. Our team can assess your current operations, identify automation opportunities and develop a tailored PLC solution that enhances your production capabilities while supporting long-term operational objectives.

Request PLC ConsultationGet In Touch

Reach out to our expert team for tailored industrial electrical solutions that keep your operations running smoothly.